Production

Production at Teknoware

Teknoware’s investment in and commitment to in-house production means that the majority of our manufacturing processes are in our own hands. This brings tangible benefits to our customers and let’s them have confidence in what we deliver.

The bulk of our products are produced and assembled in our main factory in Finland, but we also have production facilities in our subsidiaries in Poland, Malaysia, and the UK, with North American vehicle lighting customers served by a production plant in Conway, South Carolina.

All the main stages of our production are carried out in-house, from R&D to prototype production, to type testing, to serial production, to the final product assembly, and after care.

Key capabilities of our in-house production

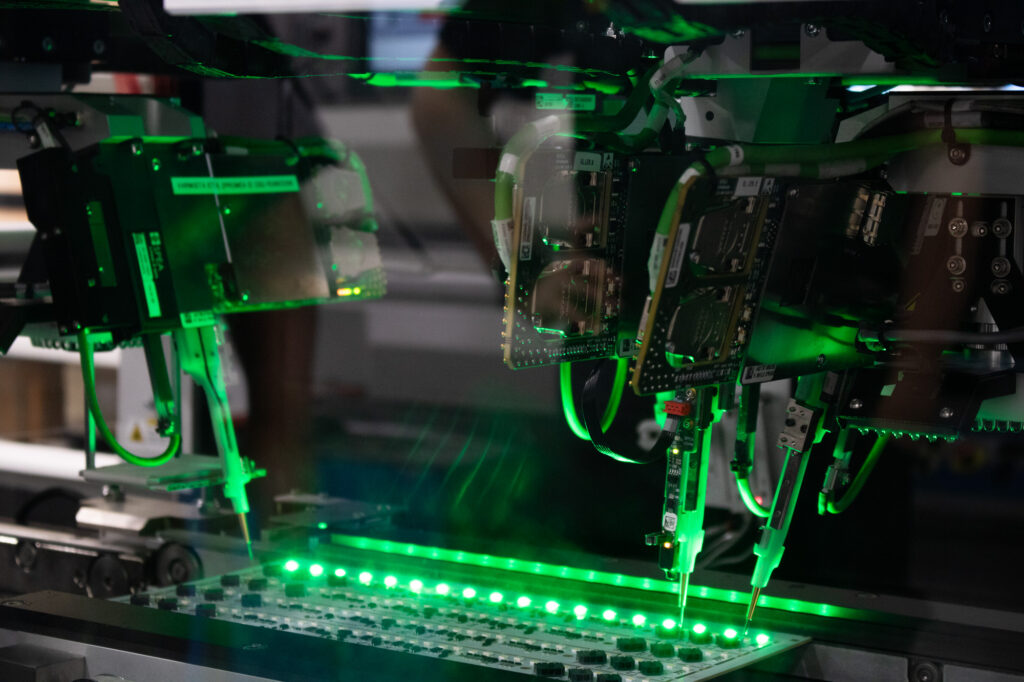

- Electronics production with multiple SMT lines and production locations in both Europe and Asia.

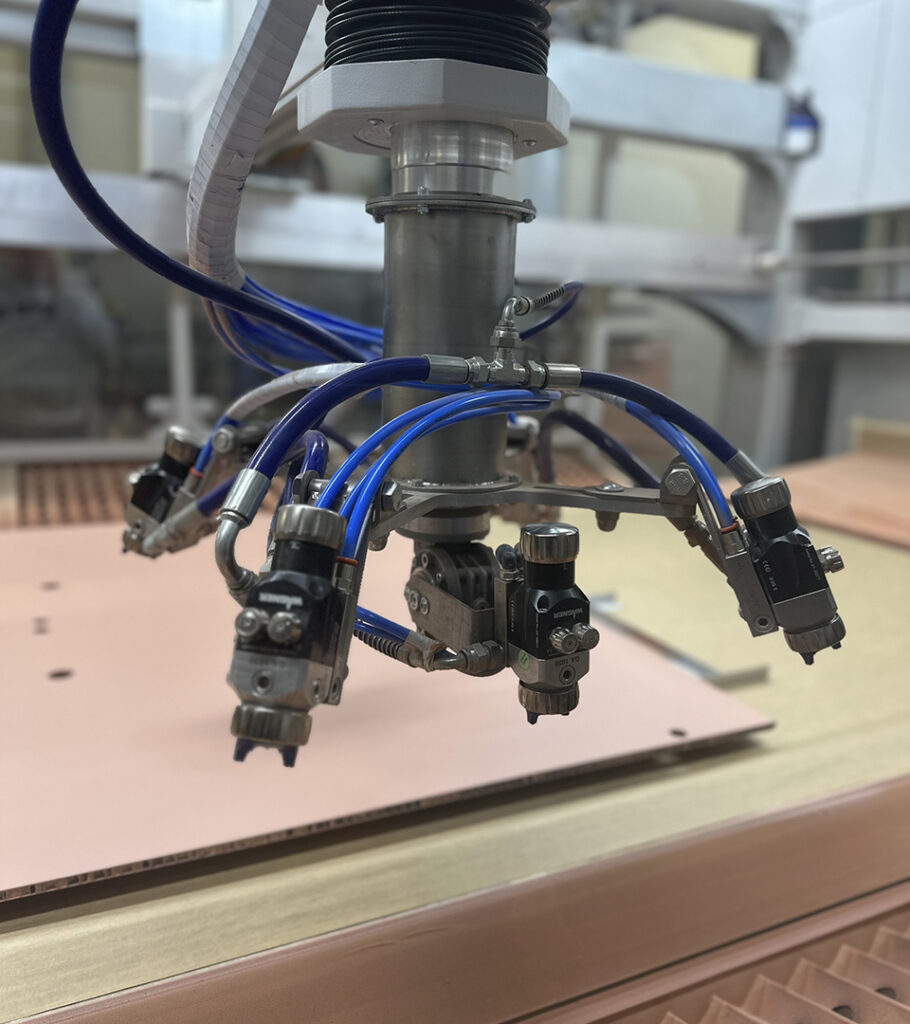

- Highly automated metal fabrication, including sheet metal turret presses and fibre laser cutting machines with automated loading and unloading. Sheet metal bending is performed using press brakes and roll formers.

- Aluminium and plastic profile machining

- Automated wiring harness production

- Bonding up to class A1 according to EN 17460

- Painting using the latest state-of-the-art equipment (in our Polish factory)

- Assembly, testing, and packing take place in close proximity to each other to get everything ready to be promptly shipped to the customer.

Automated in-house production

Teknoware can guarantee timely yet flexible deliveries thanks to our advanced production tracking system, combined with highly automated production processes.

Products are subjected to computer-controlled testing at various stages of production, and some products are even subjected to a burn-in test.

With all of our products being manufactured in our own facilities, both standard products and tailor-made systems, this gives us a lot of control over quality.

Production at Teknoware

More about Teknoware

Teknoware Lighting Solutions

Highlighted Products